Plotter Downtime: Common Causes and How to Prevent It

Plotters are a cornerstone of operations in architecture, engineering, construction, manufacturing, and design industries. Whether you're printing detailed blueprints, technical drawings, or marketing posters, a functional plotter is critical to productivity. But when plotters go down, work comes to a halt. Plotter downtime doesn't just delay timelines. It impacts client satisfaction, operational costs, and employee efficiency.

Understanding the root causes of plotter downtime and implementing the right preventive strategies—such as regular plotter maintenance and structured maintenance agreements—can make a huge difference in keeping your workflows smooth and projects on track. This article explores the most common reasons behind plotter failure and outlines practical tips to help avoid unexpected breakdowns.

Key Takeaways

- Preventive maintenance is the best defense against sudden plotter failure.

- Environmental conditions, like temperature and dust, significantly affect plotter performance.

- Many plotter issues stem from software conflicts or outdated drivers.

- User error is a common cause of downtime but can be minimized through training.

- Genuine ink, media, and parts are crucial to long-term reliability.

- A well-maintained plotter not only runs better but also extends its useful lifespan.

The Most Common Causes of Plotter Downtime

Lack of Routine Maintenance

One of the most preventable causes of plotter failure is neglecting routine maintenance. Like any piece of equipment, plotters need cleaning, calibration, and inspection. Dust buildup inside the machine can cause print heads to clog or wear out prematurely. Ink residue may harden in nozzles, leading to streaky prints or total malfunctions.

Key signs of maintenance neglect:

- Misaligned prints

- Frequent paper jams

- Inconsistent color output

- Slower-than-usual printing

Even if your plotter seems fine, skipping regular checkups can lead to bigger problems down the road. That’s why businesses often rely on professional copier and plotter repair in New Jersey to keep downtime to a minimum.

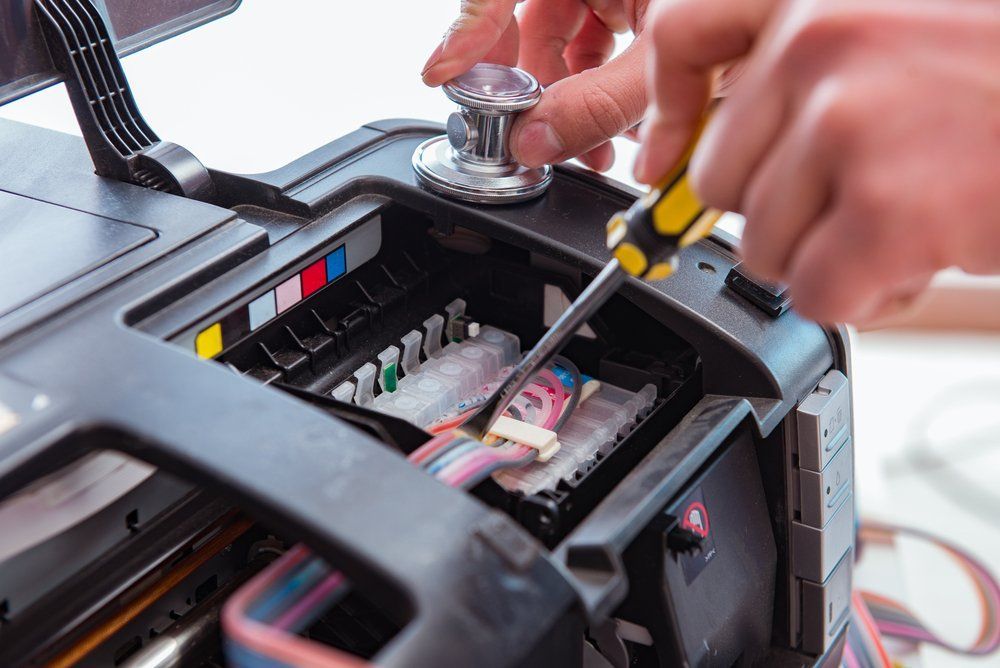

Clogged Print Heads and Ink Delivery Problems

Many plotters use thermal or piezoelectric inkjet technology, which relies on tiny nozzles to spray ink precisely. When these nozzles clog — often due to dried ink or dust — you’ll see poor print quality, banding, or missing lines. If ignored, it can lead to a complete halt in production. This issue is more common in environments where the plotter is not used daily. Infrequent printing allows ink to dry inside the print head. Low-quality ink or expired cartridges can also cause gumming and blockages.

Environmental Factors

Where your plotter is located can significantly impact its reliability. High humidity can warp paper and affect alignment. Dust and debris can collect inside the machine, causing jams and errors. Extreme temperatures can affect the consistency of ink and the lifespan of electronic components. Keep your plotter in a clean, dry, and temperature-controlled environment to minimize external stressors.

Incorrect Media or Supplies

Using the wrong type or size of paper, incompatible ink, or third-party cartridges can create chaos. These can result in jams, smudging, or even hardware damage. Non-genuine supplies may save money upfront, but they often lead to poor quality prints and may void your warranty. Always check manufacturer guidelines for compatible supplies. Stick with trusted brands for consumables.

Software or Firmware Issues

Outdated drivers, incompatible design software, or failed firmware updates can cause your plotter to freeze, crash, or misprint. This is especially common after operating system upgrades or when switching between multiple software applications. Ensure your drivers and firmware are regularly updated. Confirm that your design programs are fully compatible with your plotter model.

Mechanical Wear and Tear

Parts like belts, gears, and rollers endure wear over time. These components can degrade with extended use, causing misfeeds, grinding noises, or total machine stoppage. While mechanical parts are built to last, they will eventually need replacing. Having a preventive replacement schedule can reduce the chance of sudden mechanical failures.

User Error and Misuse

A surprising amount of downtime results from simple user mistakes. This includes:

- Loading paper incorrectly

- Skipping calibration after installing new components

- Changing settings without understanding their impact

- Forcing jammed media rather than following the correct removal procedure

Proper training for all users is essential. Investing in training minimizes costly errors and misuse.

How to Prevent Plotter Downtime

Follow a Regular Maintenance Schedule

Create a maintenance calendar that includes cleaning, lubrication, and inspection. Check with your plotter manufacturer or service provider for specific recommendations. Some tasks to include:

- Clean print heads weekly

- Wipe down rollers and trays

- Run calibration and alignment utilities

- Check ink and media levels

Most modern plotters include built-in maintenance reminders. Don’t ignore them. If you need expert assistance, professional printer repair services can help extend the life of your equipment.

Use Genuine Ink and Media

Third-party ink cartridges may be cheaper but can lead to clogs, color inconsistencies, and even hardware issues. Genuine supplies are specifically engineered for your machine, ensuring consistent performance. Using non-approved materials may also void your warranty or support agreements.

Keep Your Plotter in a Clean, Stable Environment

Avoid placing your plotter near vents, windows, or dusty areas. Use dust covers when the machine is not in use. Keep humidity and temperature within the manufacturer’s recommended range. A clean and climate-controlled environment reduces both mechanical and ink-related issues.

Train Staff Thoroughly

Every user should be trained on how to:

- Load media correctly

- Change ink cartridges properly

- Handle jams and error codes

- Run cleaning cycles

- Use design software in sync with the plotter

Offer refresher courses every few months, especially when onboarding new staff or after a major software update. Having professional support available for copy machine repairs also reduces downtime when unexpected issues arise.

Update Software and Firmware Regularly

Check for updates on your plotter’s driver, firmware, and related software tools. New updates often contain bug fixes and compatibility improvements. Set a routine schedule — perhaps monthly or quarterly — to check for and install updates.

Schedule Professional Servicing

Even with in-house maintenance, it's smart to schedule a full professional servicing once or twice a year. Technicians can identify worn components, run diagnostics, and perform deeper cleaning than you might manage internally. Signing up for managed

services ensures you have expert support readily available and long-term protection for your equipment.

Frequently Asked Questions

How often should I clean my plotter?

For most plotters, basic cleaning should be done weekly or biweekly, depending on usage. Print heads may require cleaning more frequently if you notice banding or faded prints.

Can I use third-party ink cartridges to save money?

While third-party cartridges may seem economical, they often cause print quality issues or hardware problems. Using genuine ink ensures better performance and reduces the risk of damage.

What do I do if my plotter keeps jamming paper?

Check for correct media type and loading. Clean the rollers and trays, and ensure the environment is not too humid. If the issue persists, a technician should inspect the rollers and feeder system.

Why is my plotter printing faded or streaky images?

This is typically a sign of clogged nozzles or low-quality ink. Run a print head cleaning cycle and check ink levels. If the problem remains, try replacing the cartridge or scheduling service.

Should I turn off my plotter when not in use?

Yes, turning off the plotter helps conserve power and prevents ink from drying out. Some models have a standby or sleep mode that maintains nozzle integrity while using minimal power.

Final Thoughts

Plotter downtime is more than an inconvenience. It’s a costly disruption that can affect your business’s productivity, deadlines, and reputation. While some issues are unavoidable, most are preventable with the right maintenance practices and user training. By sticking with genuine supplies, updating your software regularly, and staying on top of preventive care, you can reduce downtime dramatically. For more insights, explore our frequently asked questions to see how other businesses handle plotter upkeep.

Think of your plotter not just as a machine but as an integral part of your operation — one that deserves attention, investment, and care. A well-maintained plotter doesn’t just save you from frustration. It helps you deliver consistent, professional results day after day, project after project. To see why so many businesses trust us, check out why choose us and learn what sets our services apart.

Ready to keep your plotter running at peak performance?

Contact MachineFix today to schedule service and protect your business from costly downtime.