Best Practices for Preventing Downtime in Large-Format Printing

Large-format printing operations form the backbone of many industries, from architectural firms and marketing agencies to manufacturing companies and retail businesses. When these sophisticated machines experience unexpected downtime, the financial and operational impact can be devastating, leading to missed deadlines, frustrated clients, and significant revenue loss. Professional large-format printer service encompasses more than just reactive repairs; it requires a strategic approach that combines preventive maintenance, proactive monitoring, and comprehensive staff training to ensure continuous operation and optimal performance across your wide-format printing infrastructure.

Key Takeaways

- Implement daily maintenance routines including printhead cleaning and media path inspection to prevent 80% of common printing issues

- Establish proper environmental controls with temperature between 68-72°F and humidity levels at 45-55% to maintain print quality and equipment longevity

- Schedule professional large-format printer maintenance every 3-6 months, depending on usage volume and operating conditions

- Train operators on proper loading techniques, color management, and troubleshooting procedures to reduce user-related errors

- Maintain detailed service logs and performance metrics to identify patterns and predict potential equipment failures before they occur

- Develop relationships with certified large format printer repair technicians who understand your specific equipment and can provide rapid response times

Understanding the Critical Components of Wide Format Printing Systems

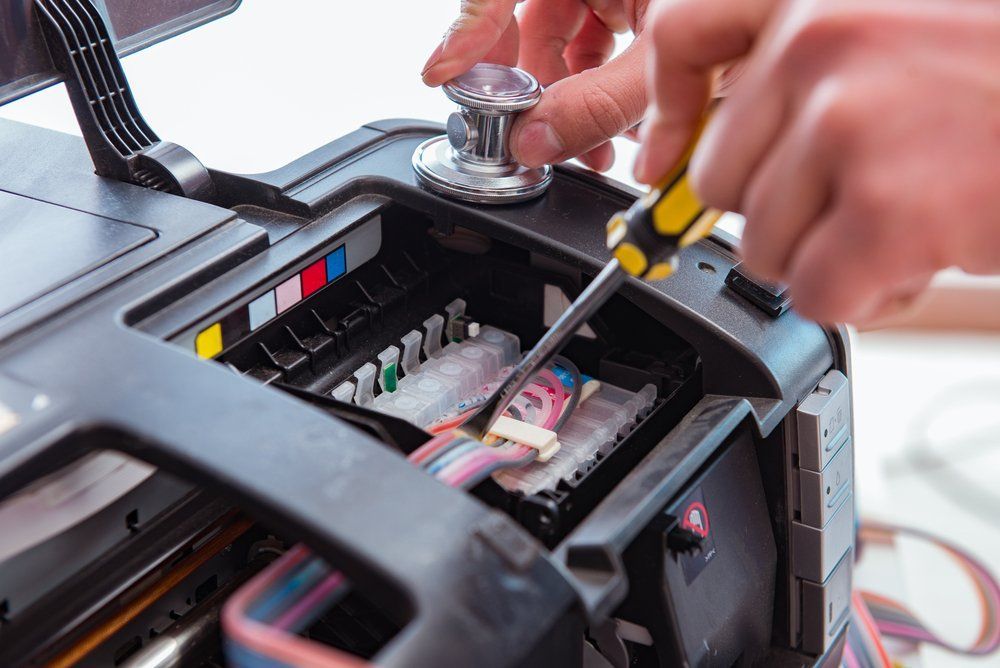

Modern big-format printing systems represent sophisticated engineering achievements that integrate multiple precision components working in perfect harmony. Understanding these critical elements enables operators and service technicians to identify potential failure points before they impact production schedules.

Essential System Components Requiring Regular Attention

- Printhead assemblies: The heart of any wide-format printing operation, these precision nozzles require daily cleaning and calibration to maintain optimal ink flow and prevent clogging that can halt production.

- Ink delivery systems: Complex networks of tubes, pumps, and reservoirs that must maintain consistent pressure and temperature to ensure reliable ink flow throughout extended printing sessions.

- Media handling mechanisms: Precision rollers, guides, and tensioning systems that must operate smoothly to prevent media jams, wrinkles, or tracking errors that can damage both substrate and equipment.

- Environmental control systems: Temperature and humidity regulation components that maintain optimal operating conditions and prevent condensation or static buildup that can affect print quality.

Professional large-format printer service technicians understand that these components operate as an integrated system, where failure of one element can cascade throughout the entire printing process. Regular inspection and maintenance of each component prevents minor issues from escalating into major breakdowns that require emergency large-format printer repair services.

Establishing Comprehensive Preventive Maintenance Protocols

Successful printer downtime prevention relies on systematic preventive maintenance that addresses both routine care and long-term equipment health. These protocols should be tailored to your specific equipment models, usage patterns, and operating environment.

Daily Maintenance Procedures

- Morning startup inspection: Check all fluid levels, verify proper temperature and humidity readings, and perform automated printhead cleaning cycles before beginning production work.

- Media path cleaning: Remove dust, debris, and ink residue from rollers, guides, and sensors using approved cleaning materials and techniques recommended by your equipment manufacturer.

- Print quality verification: Run test patterns to identify potential nozzle blockages, color inconsistencies, or alignment issues before they affect production jobs.

Weekly Maintenance Tasks

- Deep cleaning cycles: Perform thorough printhead soaking and cleaning procedures, inspect and clean ink lines, and calibrate color accuracy across all ink channels.

- Mechanical inspection: Check belt tension, lubricate moving parts according to manufacturer specifications, and inspect all electrical connections for corrosion or looseness.

- Software updates: Install firmware updates, verify driver compatibility, and backup critical configuration settings to prevent data loss during unexpected shutdowns.

Environmental Control and Workspace Optimization

Large-format printing equipment operates most reliably within specific environmental parameters. Maintaining these conditions not only prevents downtime but also ensures consistent print quality and extends equipment lifespan. Professional large-format printer maintenance includes comprehensive environmental monitoring and control systems.

Critical Environmental Factors

- Temperature stability: Maintain consistent temperatures between 68-72°F to prevent ink viscosity changes, thermal expansion of components, and condensation formation on sensitive electronics.

- Humidity management: Keep relative humidity between 45-55% to prevent static electricity buildup, media curling, and dimensional instability that can affect registration accuracy.

- Air quality control: Install appropriate filtration systems to remove dust, chemical vapors, and airborne particles that can contaminate ink systems and clog printheads.

- Vibration isolation: Position equipment away from high-traffic areas, heavy machinery, and HVAC systems that can cause mechanical vibrations affecting print quality and component alignment.

Proper workspace design includes adequate ventilation for ink vapor removal, sufficient lighting for color evaluation, and organized storage for media and supplies that maintains their quality and prevents contamination. These environmental considerations form the foundation of effective printer downtime prevention strategies.

Operator Training and Best Practices

Human error represents a significant cause of large-format printing downtime, making comprehensive operator training essential for maintaining continuous production. Well-trained operators can identify potential issues early, perform routine maintenance correctly, and troubleshoot common problems without requiring emergency large-format printer repair services.

Essential Training Components:

- Proper media handling: Training on correct loading procedures, tension adjustment, and edge guide alignment prevents the majority of media-related jams and tracking errors that can damage equipment.

- Color management protocols: Understanding ICC profiles, calibration procedures, and color matching techniques ensures consistent output quality and reduces waste from reprinting jobs.

- Troubleshooting methodology: Systematic approaches to identifying and resolving common issues like banding, color shifts, and registration problems before they require professional intervention.

- Emergency procedures: Clear protocols for safely shutting down equipment, containing ink spills, and contacting qualified large-format printer service technicians when problems exceed operator capabilities.

Regular operator training updates ensure operators stay current with new features, software updates, and evolving best practices. Documentation of training completion and competency verification creates accountability and helps identify areas where additional instruction may be needed to prevent operator-related downtime.

Monitoring Systems and Predictive Maintenance

Modern wide-format printing operations benefit significantly from implementing monitoring systems that track equipment performance, usage patterns, and potential failure indicators. These systems enable predictive maintenance strategies that address issues before they cause production interruptions.

Key Performance Indicators to Monitor

- Ink consumption patterns: Tracking ink usage rates helps predict supply needs and identify potential leaks or inefficiencies in the ink delivery system before they cause downtime.

- Print quality metrics: Regular measurement of color accuracy, density consistency, and registration precision provides early warning of printhead degradation or mechanical alignment issues.

- Component lifecycle tracking: Monitoring hours of operation, cycle counts, and maintenance intervals for critical components enables proactive replacement before failure occurs.

- Error frequency analysis: Documenting and categorizing equipment errors helps identify recurring issues that may indicate underlying problems requiring professional large-format printer maintenance.

Advanced monitoring systems can integrate with maintenance management software to automatically schedule service appointments, order replacement parts, and alert operators to developing issues. This proactive approach significantly reduces emergency repair situations and extends equipment lifespan through timely intervention.

Supply Chain Management and Parts Inventory

Effective supply chain management forms a critical component of printer downtime prevention strategies. Having the right parts, consumables, and supplies available when needed prevents extended downtime while waiting for deliveries, especially for specialized components that may have longer lead times.

Strategic Inventory Management

- Critical spare parts: Maintain inventory of high-wear components like printheads, drive belts, and filters that can be quickly replaced by trained operators or service technicians during scheduled maintenance.

- Consumable supplies: Stock sufficient quantities of ink cartridges, cleaning solutions, and maintenance kits to prevent production delays when supplies run low unexpectedly.

- Emergency contact protocols: Establish relationships with suppliers who can provide expedited shipping for urgent parts and maintain contact information for certified large-format printer repair services.

- Quality assurance: Verify that all supplies meet manufacturer specifications and are stored properly to maintain their effectiveness and prevent contamination that could damage equipment.

Regular review of inventory levels, usage patterns, and supplier performance helps optimize stock levels while minimizing carrying costs. This balanced approach ensures availability without excessive investment in slow-moving inventory that may expire or become obsolete before use.

Frequently Asked Questions

How often should I schedule professional large-format printer maintenance?

Professional maintenance should be scheduled every 3-6 months depending on your usage volume and operating environment. High-volume operations or challenging environmental conditions may require more frequent service to maintain optimal performance.

What are the most common signs that my wide format printer needs repair?

Watch for print quality issues like banding, color inconsistencies, or missing nozzles, along with mechanical problems such as media feeding errors or unusual noises. These symptoms often indicate developing issues that require prompt attention to prevent major failures.

How can I extend the lifespan of my big-format printing equipment?

Consistent daily maintenance, proper environmental controls, and regular professional servicing significantly extend equipment life. Operator training and quality supplies also play crucial roles in preventing premature wear and damage.

What should I do if my printer experiences an unexpected breakdown?

Safely shut down the equipment following manufacturer procedures and contact qualified large-format printer repair technicians immediately. Avoid attempting complex repairs yourself, as this may cause additional damage or void warranty coverage.

What’s the difference between an MFP and a regular copier?

Look for certified technicians with experience on your specific equipment models, rapid response times, and comprehensive service offerings including preventive maintenance. Local providers often offer better response times and can develop deeper understanding of your operational needs.

Final Thoughts

Preventing downtime in large-format printing requires a comprehensive approach that combines proactive maintenance, environmental control, operator training, and strategic partnerships with qualified service providers. By implementing these best practices and maintaining consistent attention to equipment health, businesses can achieve reliable production schedules, consistent print quality, and optimal return on their printing equipment investments. The key lies in treating your wide format printing systems as critical business assets that deserve the same level of care and attention as any other essential production equipment.

Prevent costly downtime with professional large format printer maintenance. Schedule your service consultation today.

Reference:

https://www.ilearningplus.org/courses/wide-format-printing-essentials